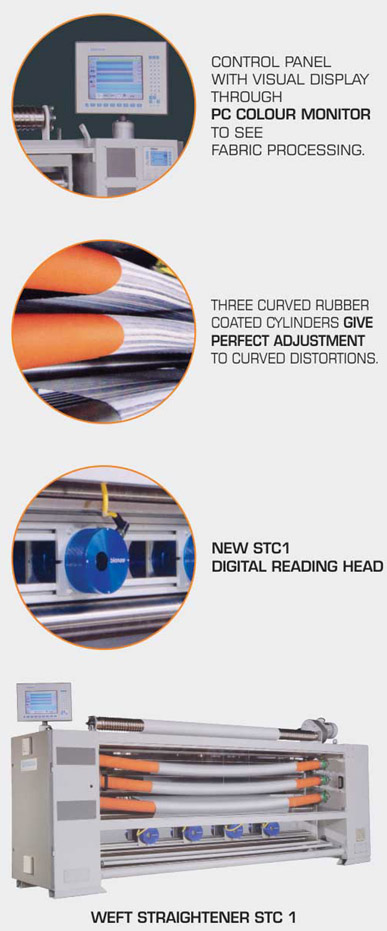

‘BIANCO’ WEFT STRAIGHTENER STC 1

SUITABLE FOR ALL KIND OF WOVEN AND KNITTED FABRICS

THE BIANCO STC1 WEFT STRAIGHTENER CORRECTS DIAGONAL OR CURVED DISTORTIONS. THE FABRIC PASSES ALTERNATIVELY BETWEEN CURVED AND DIAGONAL ROLLERS AND BETWEEN THE OPTIC READING HEADS. WHEN THE MOBILE FRAME CARRYING THE ROLLERS BEGINS TO OSCILLATE, HALF THE FABRIC IS PULLED FROM THE CENTER TO THE CORRESPONDING EDGE AS HALF RELAXES THEREBY ENABLING DIAGONAL DISTORTIONS TO BE CORRECTED. THE OTHER SET OF ROLLERS HAS A CURVED AXIS WHICH CAN BE AIMED SO AS TO PRESENT A MORE OR LESS MARKED CONVEXITY TOWARDS THE FABRIC WOUND AROUND IT AND THEREBY APPLY TO THE FABRIC, A FORCE WHICH GRADUALLY INCREASES FROM HE EDGES TO THE CENTER. THIS FORCE ENABLES CURVED DISTORTIONS TO BE CORRECTED.

THE READING BRIDGE IS AVAILABLE IN VARIOUS CONFIGURATIONS WITH FIXED MOBILE OR SCANNING SENSORS, SINGLE SCAN REFLECTION READING OR TWIN SCAN REFLECTION AND TRANSPARENCY READING. THE NUMBER OF HEADS VARY I.E. 4/6/8 HEADS DEPENDING ON THE WIDTH OF THE FABRIC. THE READING HEADS ARE WELL EQUIPPED WITH A TEMPERATURE SENSOR WHICH STOPS THEIR OPERATION WHEN THE TEMPERATURE INSIDE THE HEADS REACHES 55° C. THE NEW GENERATION READING HEADS OF STC1 DETECT WEFT DISTORTIONS IN THE FABRIC LEAVING THE WEFT STRAIGHTENER AND SUPPLY A SIGNAL TO THE CONTROL SYSTEM WHICH INTERPRETS THE SIGNAL, PROCESSES IT AND TRANSFORMS IT INTO CONTROL PULSES TO THE SKEW/BOW CORRECTION ROLLER MOTORS.