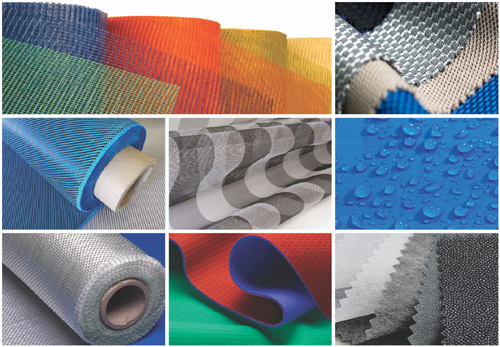

TECHNICAL TEXTILE / COATINGS

- AUTOMOTIVE FURNISHING FABRICS

- AEROSPACE APPLICATION FABRICS

- CONSTRUCTION APPLICATION FABRICS

- DECORATIVE FURNISHING FABRICS

- ENGINEERING & PACKAGING FABRICS

- TECHNICAL APPAREL

- SPORTS & LEISURE

- MEDICAL & HYGIENE APPLICATIONS

- FLAME PROOF FABRICS

- WATER PROOF FABRICS

- COATINGS OF NON WOVENS FOR

- AUTOMOBILES

(TYRE CORDS, SEAT COVER, CLADDING, INSULATING)

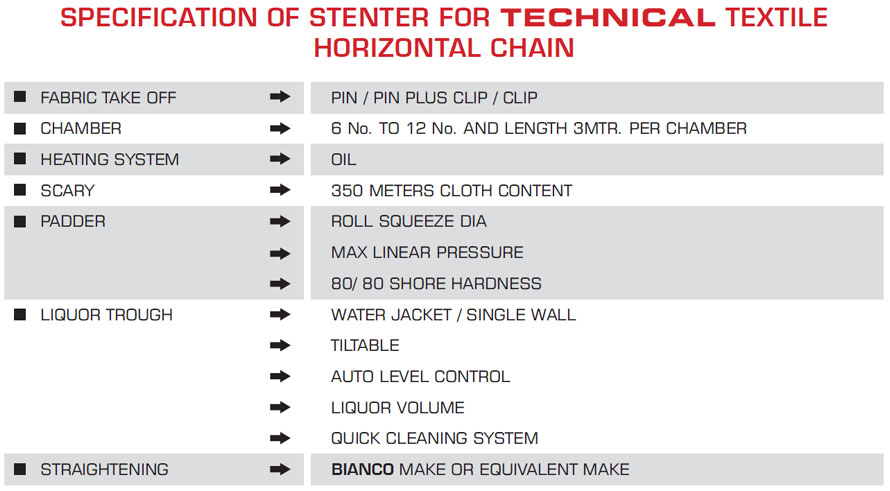

KEY FEATURES OF STRETCH LINE STENTER MACHINE

FOR TECHNICAL TEXTILE & COATING

- TECHNICAL TEXTILE ARE DEFINED AS TEXTILE MATERIALS AND PRODUCTS USED PRELIMINARY FOR THEIR TECHNICAL PERFORMANCE AND FUNCTIONAL PROPERTIES RATHER THAN THEIR AESTHETIC OR DECORATIVE CHARACTERISTICS.

- AWARENESS OF THE ADVANCED VALUES IN TEXTILES HAS AN INFLUENCE ON TRADITIONAL MANUFACTURING TO APPRECIATE THE SPIRIT OF INNOVATION, PLACE MIND SET BEYOND YARN AND GREY CLOTHS AND ATTEMPT TO AN ENHANCED CONTRIBUTION TO TECHNICAL TEXTILE DEVELOPMENT.

- MOSTLY COATING AND SUBSEQUENTLY DRYING ON STENTER IS THE MAJOR VALUES ADDITION, PROCESS WITH MICRO LEVEL CONTROL WHILE APPLICATION AND DRYING.

STRETCHLINE-1100 STENTER

FOR TECHNICAL TEXTILE / COATING

- TECHNICAL TEXTILE ARE DEFINED AS TEXTILE MATERIALS AND PRODUCTS USED PRELIMINARY FOR THEIR TECHNICAL PERFORMANCE AND FUNCTIONAL PROPERTIES RATHER THEIR AESTHETIC OR DECORATIVE CHARACTERISTICS’

- AWARENESS OF THE ADVANCED VALUES IN TEXTILES HAS AN INFLUENCE ON TRADITIONAL MANUFACTURING TO APPRECIATE THE SPIRIT OF INNOVATION, PLACE MIND SET BEYOND YARN AND GREY CLOTHS AND ATTEMPT TO AN ENHANCED CONTRIBUTION TO TECHNICAL TEXTILE DEVELOPMENT.

- TODAY TEXTILE FIBERS ARE SIGNIFICANTLY SERVING APPLICATION INCLUDING AUTOMOTIVE, AEROSPACE, MEDICAL & HYGIENE, CONSTRUCTION, INTERIORS, ENGINEERING AND PACKAGING, TECHNICAL APPAREL, SPORTS AND LEISURE ETC. WITH SUCH EMERGING TEXTILE, THE PROCESS AND ITS CONTROL ARE KEY CRITERIA TO LOOK INTO.

- POLYOLEFIN (POLYETHYLENE & POLYPROPYLENE) AND POLYESTER ACCOUNT FOR 50% OF THE FIBRE CONSUMPTION FOLLOWED BY GLASS AT 15% AND JUTE AT 14%.

- APPLICATION OF CHEMISTRY WITH COATING IN CONTROL METHOD.

- MOSTLY COATING AND SUBSEQUENTLY DRYING ON STENTER IS THE MAJOR VALUES ADDITION PROCESS WITH MICRO LEVEL CONTROL WHILE APPLICATION AND DRYING.

- HOMOGENEOUS CIRCULATING AIR WITH UNIFORM TEMPERATURE DISTRIBUTION ( UP & DOWN ) WHICH IS MOST AND MORE FOR COATING PROCESS.

- SYMMETRICAL EXHAUST AIR DUCT.

- ATEX CERTIFIED VERSION FOR FEW HAZARDOUS CHEMISTRY.

- CONDENSATE PROTECT OPTION.

TECHNICAL TEXTILE FIBER

TECHNICAL TEXTILE FIBER

ALMOST 90% OF THE FIBERS (LINK TO TEXTILE FABRIC) UTILIZED TO TECHNICAL TEXTILES BELONG TO THE CATEGORY OF CONVENTIONAL FIBERS AND THE FIBERS SPECIALLY DEVELOPED TO SPECIFICALLY USE IN TECHNICAL TEXTILES ARE NOT ONLY EXPENSIVE BUT OFTEN HAVE LIMITED APPLICATIONS.

TECHNICAL TEXTILE PRODUCTS

WITHIN THE COMPOSITES INDUSTRY, WOVEN, KNITTED, BRAIDED, NON WOVEN (LINK)AND WOUND REINFORCEMENTS PRODUCED FROM GLASS, CARBON FIBER AND ORGANIC POLYMER MATERIALS LIKE ARAMIDS ARE PRESENTLY ACCEPTED AS TECHNICAL TEXTILE PRODUCTS.